March 2017

Planning & Precision Results in Successful Crane Operation at Northwestern University Mudd Hall

By: Kasie Mathena, Senior Project Manager at Northwestern University Mudd Hall

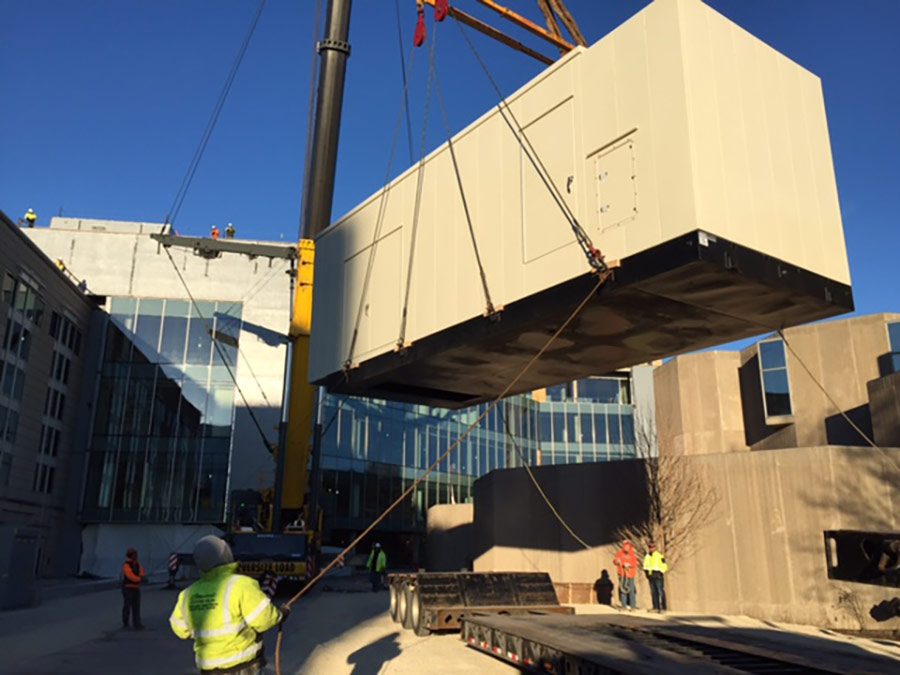

In May of 2016, Northwestern University informed Walsh of their intent to relocate a new generator from grade level to the roof of the new five-story Mudd Hall. Planning started immediately, and Walsh engaged Central Crane to determine the best feasible option. It was determined the pick was feasible, but only from one location which happened to be sandwiched between Searle Hall and Cook Hall. In addition, and through information garnered from a complex caisson operation, we knew this location was full of underground structures and utilities and due diligence was needed. With the help of ground heating mats, crews vacuum excavated the entire area of the future crane pad to better define the exact locations of these structures and determine if the large loads were problematic.

With actual as-built conditions established and engineering conducted by the University, the best solution to preserve the underground structures was a very robust crane mat consisting of filter fabric, three feet of stone, and wood lagging. The team shored a nearby steam vault and elected to brace an area-well just south of the crane setup. In addition to the pad, the outriggers were placed on 4'x8'x1" plates to further spread the loads.

Knowing we could physically pick the generator without compromising any of the underground structures, it was time to focus on the pick itself. This portion of the planning started about eight weeks prior to the pick. The proposed crane plan dictated much of the logistics affecting both the University campus as well as the jobsite. Numerous meetings with the University were held to discuss evacuating Searle Hall, to review the large laydown space needed in the adjacent University parking lot, and to gain approval from the University's Risk Management department and Campus Police.

Upon gaining final approval from the University, the last three weeks of planning were about dotting the i's and crossing the t's. Our team carefully reviewed the pick plan, and also engaged other experts to review. It was determined to be an 85% capacity pick with a wind threshold of 18 mph. Being near the lake, it was likely the pick could be called off by the team or the operator. JHAs and THAs were submitted by Central Crane and Standard Cartage and reviewed by Walsh. Weights of the generator were confirmed through the trucking company's bill of lading and additionally confirmed with the crane itself prior to placing the generator.

On the day of the pick, the team gathered for a pre-pick safety review at 5:30 AM. Thirty minutes later, Walsh and Northwestern police swept Searle Hall to ensure it was evacuated, and flaggers remained at entrances to keep people out. Meanwhile, the rigging was installed and further inspected. At approximately 7:00 AM, with the wind speed at 11 mph, we confirmed Searle was still evacuated and proceeded to make the lift. It took five minutes to fly the generator through the air and another five minutes to precisely place it. Work was completed by 7:10 AM in time for Searle Hall to start classes. Planning that started in May of 2016 and continued to be planned in earnest for the last three months was successfully completed in 10 minutes.

Watch a video of the crane lift at Northwestern University's Mudd Hall.

Note: A job well done by the Walsh team consisting or Will Scott, Jeff Dudley, Jorge Arreola, Steve Saigeon, DJ Murray, Maureen Ramirez, Shontae Cobb, Elizabeth Crovetti, Carlos Norrick, Adam Pummer, and Stan Keagle. Special recognition is deserved by Will Scott; he was the point person for the planning. His natural curiosity, motivation, resilience, and grit are a big part of why the pick was a success and able to happen when it did. Also, special recognition to Jeff Dudley for letting us tap into his wealth of crane knowledge.